Making a better product in a better way.

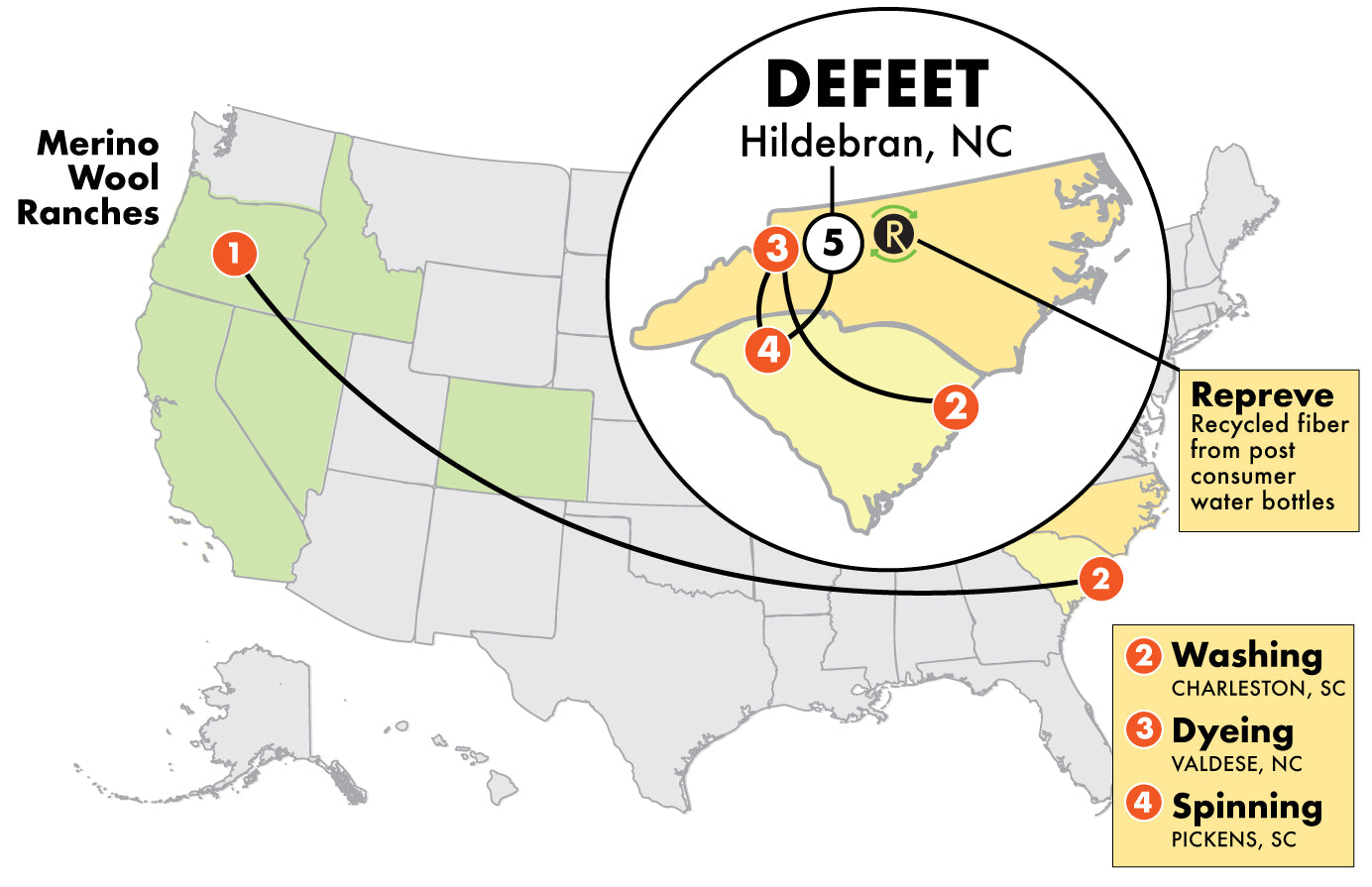

As a small North Carolina-based microsockery, DeFeet has always prioritized the 3 R's: Reduce, Reuse, Recycle. We engineer a long-lasting durable product that doesn't get thrown away after a few months, and maintain a local supply chain to keep manufacturing right here where it started. We sought out a high-quality recycled fiber to pair with our USA-grown Merino wool, and found it with Repreve.

Because we're small, we're agile. When we see a problem, we fix it. When we see a way we can improve, we give it a try. No need to submit an idea to a committee for review and approval and build out a flow chart - we just make it happen.

When we say local supply chain, we mean it.

When many companies moved manufacturing overseas, we prioritized finding business partners here in the USA.

Our Fibers

Manufacturing

DeFeet owns and operates its own factory in the foothills of the Blue Ridge Mountains of North Carolina. We have manufactured here since we opened our doors in 1992. Over the past 32 years we have consistently upgraded our facilities to become more efficient and environmentally conscious.

By using motion sensors, more efficient lighting and cold water washing we have been able to cut our annual electric use by as much as 67%.We have invested in equipment for the specific purpose of cutting our water usage by more than half from when we started the company. The results have been incremental on a year-over-year basis. We do not yet have a precise figure yet to share over say the past ten years, however we are looking forward to publishing the results of this research.

Manufacturing

DeFeet owns and operates its own factory in the foothills of the Blue Ridge Mountains of North Carolina. We have manufactured here since we opened our doors in 1992. Over the past 32 years we have consistently upgraded our facilities to become more efficient and environmentally conscious.

By using motion sensors, more efficient lighting and cold water washing we have been able to cut our annual electric use by as much as 67%.We have invested in equipment for the specific purpose of cutting our water usage by more than half from when we started the company. The results have been incremental on a year-over-year basis. We do not yet have a precise figure yet to share over say the past ten years, however we are looking forward to publishing the results of this research.

Does recycled fiber really make a difference?

Repreve's process of making their recycled yarn reduces water usage by almost 20% compared to virgin polyester, keeping more than 25 billion plastic bottles out of landfills!

Repreve makes their recycled yarn by transforming local post-consumer waste into an amazing fiber. Their process embeds properties like wicking, adaptive warming and cooling, water repellency, and more at the fiber level.

Additional Sustainability Efforts

Waste management isn't just about taking out the trash.

Our first priority in reducing waste is engineering and manufacturing a high quality durable product that lasts for years, which means our customers don't have to replace worn out socks every year. Our microsockery production team also knits in small batches to reduce overstock and liquidation.

From the days of racing with First Flight and being sponsored by Shane and DeFeet these socks have been with me every pedal stroke of my journey. These socks are older than my kids and are indestructible."

- Derrick Styles

Circularity on a local scale.

Material Return, a local company focused on custom circularity, transforms our region’s textile waste in a hyper-localized supply chain of 75 miles into ReturnTex™ yarn.

We donate our sock seconds. These socks may have small cosmetic issues visible to sock critics like us, but they’re still durable high-quality socks! They are also sold in our grab bags, or at events.

We even recycle the polypropylene yarn cones, which are picked up and recycled locally into different products (including dog bowls!).

and, of course, we CYCLE!

If there's one thing we really take seriously, it's our bikes. If we can get there on a bike, we do. If we're playing, we're on bikes. We take care of our trails, we pack out what we take in, and we lose no opportunity to appreciate Mother Nature's playground.

and, of course, we CYCLE!

If there's one thing we really take seriously, it's our bikes. If we can get there on a bike, we do. If we're playing, we're on bikes. We take care of our trails, we pack out what we take in, and we lose no opportunity to appreciate Mother Nature's playground.